Difference between revisions of "MainPage:Nuclear:KaonDetector:AerogelDetectorConstruction"

| Line 160: | Line 160: | ||

[[File:BoxVerticalBars.jpg|thumb|center|250px|2x Diffusion Box Vertical Bar, that will allow to hold the aerogel trays with the diffusion box]] | [[File:BoxVerticalBars.jpg|thumb|center|250px|2x Diffusion Box Vertical Bar, that will allow to hold the aerogel trays with the diffusion box]] | ||

| valign="top"| | | valign="top"| | ||

| − | [[File:Interface_Attachment_Plate.jpg|thumb|center|x200px|Interface plate and Attachment plate | + | [[File:Interface_Attachment_Plate.jpg|thumb|center|x200px|Interface plate and Attachment plate on the milling cutter. They are going to hold all the detector on a trail at the SHMS.]] |

|} | |} | ||

Revision as of 22:12, 10 November 2011

| This page is under construction. It requires a review! |

| ⇐ Back to the Kaon Detector page |

Checklist of the progress on the milling

The following checklists are an overview of the main parts of the detector and the progress on its construction. As it is going to be constructed one diffusion box and three aerogel trays, these list provide the status on the progress for each piece of all of the items.

Last update: November 10, 2011

(Legend: ![]() is ready,

is ready, ![]() is being milled at the moment,

is being milled at the moment, ![]() was cutted (water cutting) for future milling and

was cutted (water cutting) for future milling and ![]() is not milled)

is not milled)

It is going to be constructed three trays (aerogel boxes). The following list includes the milling parts required for all of these trays.

(Legend: ![]() is ready,

is ready, ![]() is being milled at the moment and

is being milled at the moment and ![]() is not milled)

is not milled)

Materials and pieces machining

The materials had been ordered by Dr. Marek. Almost all the structural pieces (aluminum pieces) was delivered on October 10th, at CUA. Paul and Michael started milling the first piece of our new detector on October 13!

This construction is being conducting under a collaboration between the Nuclear Physics Group and the Vitreous State Laboratory group (VSL).

Ready pieces

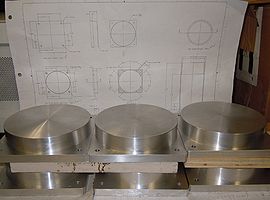

As the machining process is going on, the first pieces of the Kaon Aerogel Detector are being ready! Paul and Michel are working at the CUA Machine Shop and the progress of the construction can be verified in the following pictures.

Some of the materials require the cut of large pieces, for instance, the side plates of the diffusion box and also the PMT's end plates. These cuttings are related to the pieces that will hold the PMTs in the detector. As the PMTs have an overall diameter of 5", holes with this dimensions were required in that material.

As a first step on the machining of these pieces, they were send to a company for a water cutting.